By loading the video, you agree to YouTube's privacy policy.

Learn more

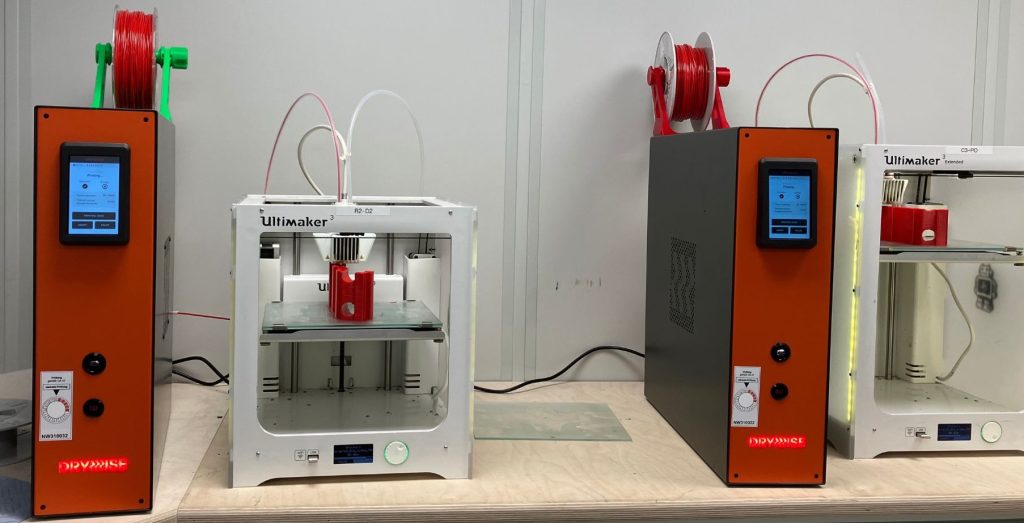

Watch the video to learn how IGESTEK 3D prints injection molds and thermoforming tools in the development of lightweight solutions for the automotive industry.

Located in the Bilbao region in Spain, IGESTEK is a leading company specializing in the development of lightweight solutions for the automotive industry using plastics and composite materials.

The company develops and integrates different hybrid processing techniques to manufacture composite components, which can then be implemented by Tier 1 automotive suppliers and original equipment manufacturers (OEMs) to produce parts for high-end cars and motorcycles.

IGESTEK’s team uses 3D printing throughout the product development process, from the conceptual design phase to verify geometries to the detailed design phase for the realization of functional prototypes. They also use 3D printing to manufacture rapid tooling, such as inserts for plastic injection molds or thermoforming tools for composites. Learn how IGESTEK improves the speed of development, reduces costs, and ensures an agile response to possible problems that may arise.

Find out more by reading the full user story here.

MATERIAL Resin

MANUFACTURING PROCESSVAT Photopolymerization

DRIVERProduct Quality

STEPS / INTERVENTIONS Supply chain optimisation

OUTCOME Quality improvement

ENABLERSchange of mindset

Ridig 10K Resin, High Temp Resin, Draft Resin