Use case

Achieving Global 3D Printing Consistency at Ford Werke GmbH

Category

Prototype, Series Manufacturing

Branch

Automotive, Mobility

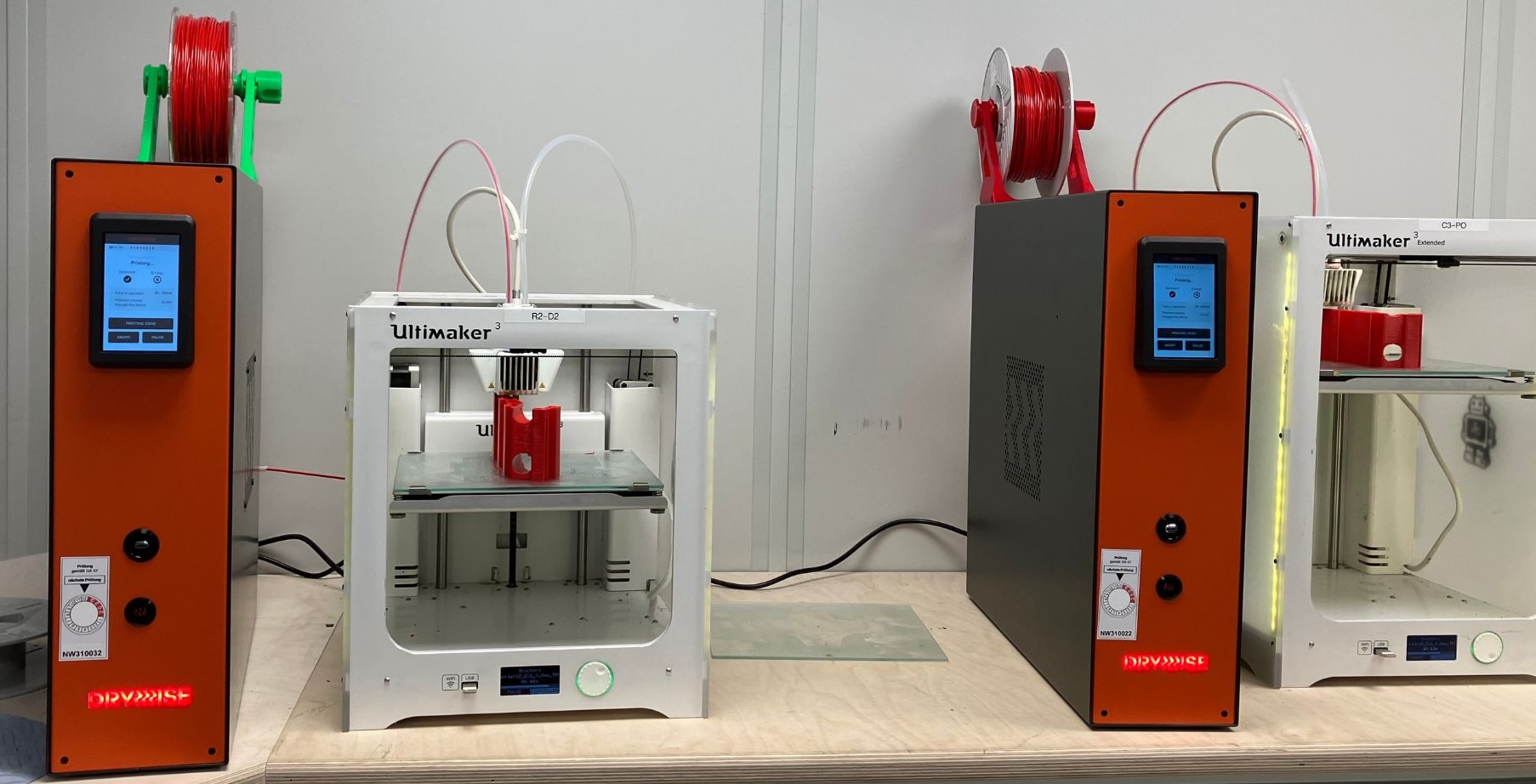

Ford Werke GmbH's 3D Printing Center in Cologne, operational since early 2023, uses advanced 3D printers for prototyping and manufacturing in the automotive sector.

They faced challenges with hygroscopic materials like TPU, which absorb moisture and affect print quality. Ford implemented Drywise, a tool ensuring consistent, optimal printing conditions, to overcome these challenges. This resulted in improved print quality, reduced humidity issues, and achieved consistent high-quality part production across various locations, supporting Ford’s transition to electric vehicles and a carbon-neutral future.