Function integration despite limited space

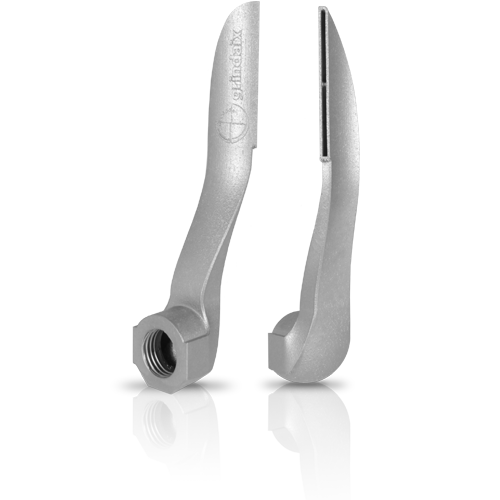

Additive Manufacturing is a disruptive technology, that enables the production of precise fitting, high-efficient and individual components. The nozzle project of Bionic Production with Grindaix GmbH and TRUMPF shows the possibilities of 3D printing.

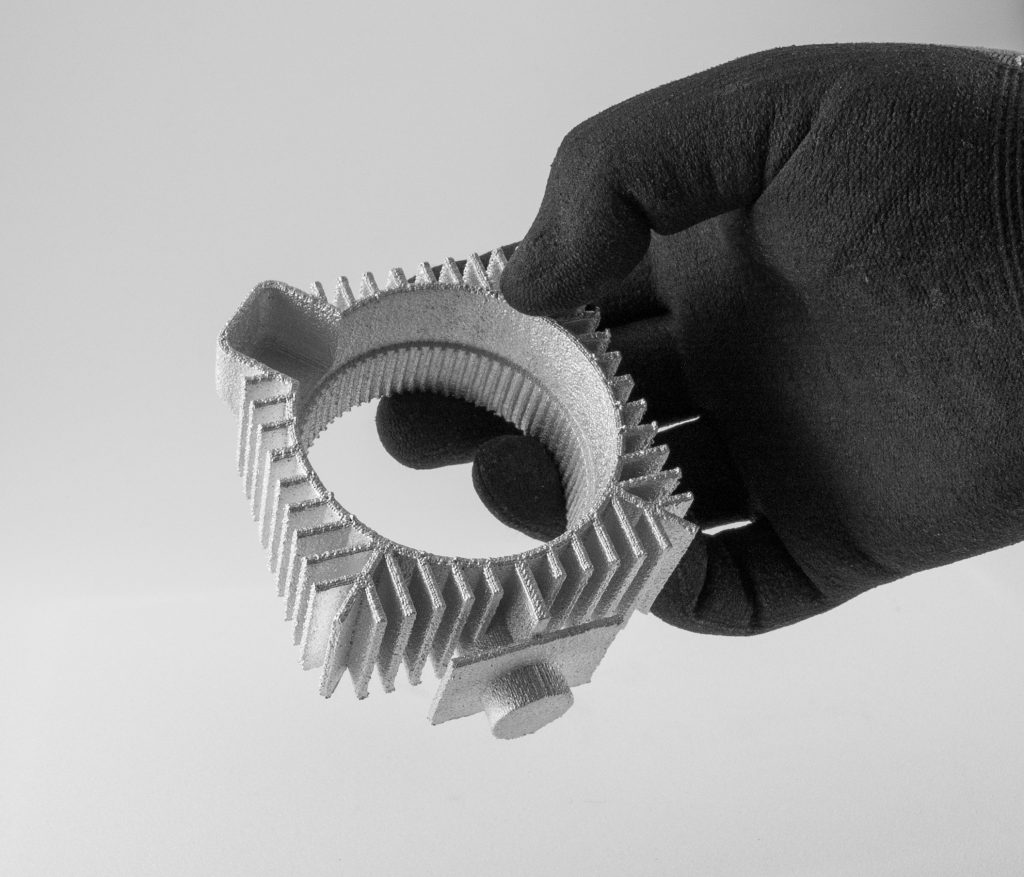

The biggest challenge in internal diameter cylindrical grinding lies in the limited space between the part and the tool for the cooling nozzle. Therefore, the lubricoolant required for the grinding is usually injected from the outside. For this purpose the Grindaix experts were looking for optimization options in the 3D design of the nozzle.

Bionic Production took the specifications provided by Grindaix and TRUMPF for the nozzle and created the perfect model in a step-by-step process. Prototype production allowed the team to implement every possible optimization with a reasonable timeframe and budget.

This resulted in a significant cost reduction of 51 % as well as a weight reduction of 25 %.

MANUFACTURING PROCESSPowder Bed Fusion

STEPS / INTERVENTIONS Function integration

stainless steel 1.4404