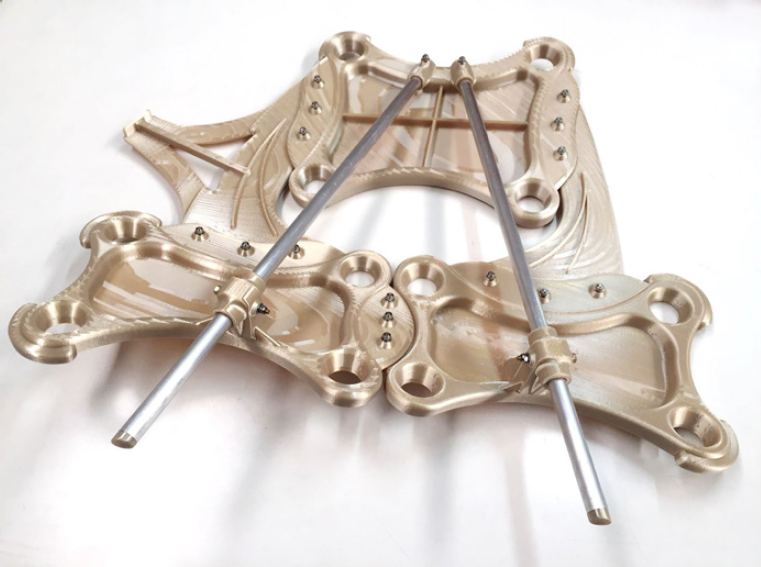

In a project for Aernnova, an Airbus provider, Indaero used 3D printing to optimize tooling for the manufacture of an Airbus NH90 helicopter. Traditionally, Indaero used aluminum tooling to attach a slide box onto the interior panel of the helicopter wing. Weighing 12 kilos, the tool required two operators to hold it against the panel while marking the drill holes. With 3D printing, the team redesigned the tool with a curvature matching the panel structure and the capability to stand on its own with the help of two aluminum bars. As a result, Indaero provided Aernnova with a more effective tool, nine kilos lighter than its predecessor.

MATERIAL Ultem

MANUFACTURING PROCESSFused Filament Fabrication

DRIVERLead time reduction

Ultem 9085