The customer from the mechanical engineering sector had been using the required components in some cases for several decades. This meant that the spare parts were no longer available at all or only available in small quantities. In addition, the parts data were only available as 2D drawings. Methods, processes and feasibility studies for 3D printed metal parts were needed to ensure an efficient part supply. The main project goals included:

- simplification of the spare part supply

- development of quality assurance processes for 3D printed spare parts

- examination of the framework conditions for the digitalization of storage and demand planning

Consulting approach:

- Selection of sample parts and digitization

- Conception of the acceptance process and QS based on the experience in other industries

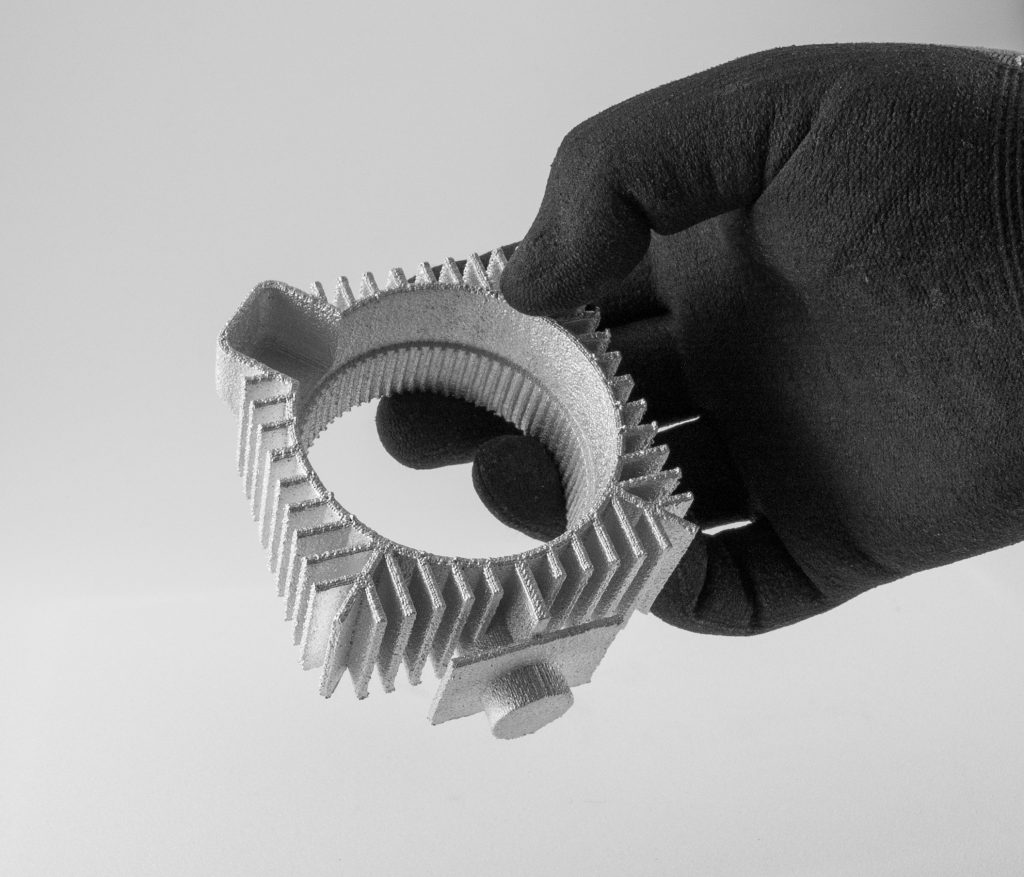

- Manufacturing of the parts (3D printing)

- Inspection of the parts according to the previously defined acceptance process

- System tests and function test by the client

- Evaluation / recommendation of the next steps to set up a virtual warehouse

Results:

- Digitization, 3D printing, post processing and successful test of the first parts

- Development of a standardized QS-process with experiences in the automotive and medical industry