Category

Series Manufacturing, Tooling

Branch

Aerospace, Automotive, Gas & Oil, Industry, Machinery and Tooling, Rail

CHALLENGE

The motor for the ElemX 3D Printer is located inside the heated build chamber. When exposed to high temperatures during operation, it can jeopardize motor functionality. This results in product delays and costly redesigns.

While CNC machining methods are often ideal for simple geometries and quick solutions, this application requires a more unique approach.

So how can we quickly create a custom cooling prototype that functions immediately in the operational environment?

SOLUTION

As CNC is not suitable for this geometry – we turned to 3D Printing.

The PLA printed prototype was designed to test form and fit but lacks function.

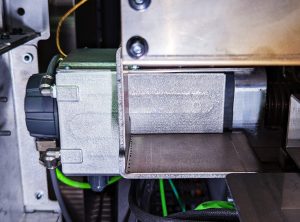

We then turned to ElemX to print a functional part. Made using Al 4008, the cooling jacket weighs approximately 760 grams and took 15 hours to complete.

RESULT

The Cooling Jacket made with ElemX was successfully installed on ElemX.

The cooling jacket took 15 hours to complete.

The internal cooling channels are 2 mm wide and the external fins measure at ~2.5 mm wide, so coolant can now flow freely through metal jacket and continue cooling the motor for smooth operation.

STEPS / INTERVENTIONS Function integration

Aluminum 4008